Capabilities

Capabilities

3-Omega

The 3-Omega method [1, 2, 3] is a frequency-domain transient electrothermal technique for measuring the thermal conductivity of bulk and thin film samples. Our in-ambient 3-Omega system includes 1-omega signal subtraction and accommodates a sample temperature peltier-controlled to within Tambient +/- 70 C. The sample is mounted within a 4-probe electrical probe station with a low power optical stereo microscope and illumination. The four micropositioners make it quick and easy to make repeatable electrical contact to as-fabricated heater lines, while a 5th coarse micropositioner makes placement of the temperature controller’s feedback thermocouple easy and precise. We drive our heater lines with a Keithley 6221 AC Current Source instead of a voltage source, to optimally match experimental conditions with the theoretical model. We detect first and third harmonics of the voltage with a dual-demodulator Ametek Lock-In Amplifier. The system is also compatible with our cryostat for cryogenic temperature and high vacuum measurements.

The 3-Omega method [1, 2, 3] is a frequency-domain transient electrothermal technique for measuring the thermal conductivity of bulk and thin film samples. Our in-ambient 3-Omega system includes 1-omega signal subtraction and accommodates a sample temperature peltier-controlled to within Tambient +/- 70 C. The sample is mounted within a 4-probe electrical probe station with a low power optical stereo microscope and illumination. The four micropositioners make it quick and easy to make repeatable electrical contact to as-fabricated heater lines, while a 5th coarse micropositioner makes placement of the temperature controller’s feedback thermocouple easy and precise. We drive our heater lines with a Keithley 6221 AC Current Source instead of a voltage source, to optimally match experimental conditions with the theoretical model. We detect first and third harmonics of the voltage with a dual-demodulator Ametek Lock-In Amplifier. The system is also compatible with our cryostat for cryogenic temperature and high vacuum measurements.

Hot Disk

The Transient Plane Source (TPS) or Hot Disk method [1, 2] is a time-domain transient electrothermal technique for rapid high-throughput measurements of the thermal conductivity, thermal diffusivity, and specific heat for large bulk solids, liquids, pastes, and powders, requiring minimal sample prep. We use a commercial model TPS 2200 Hot Disk from Thermtest, capable of measuring samples ranging from k = 0.01 W/m-K to 500 W/m-K.

The Transient Plane Source (TPS) or Hot Disk method [1, 2] is a time-domain transient electrothermal technique for rapid high-throughput measurements of the thermal conductivity, thermal diffusivity, and specific heat for large bulk solids, liquids, pastes, and powders, requiring minimal sample prep. We use a commercial model TPS 2200 Hot Disk from Thermtest, capable of measuring samples ranging from k = 0.01 W/m-K to 500 W/m-K.

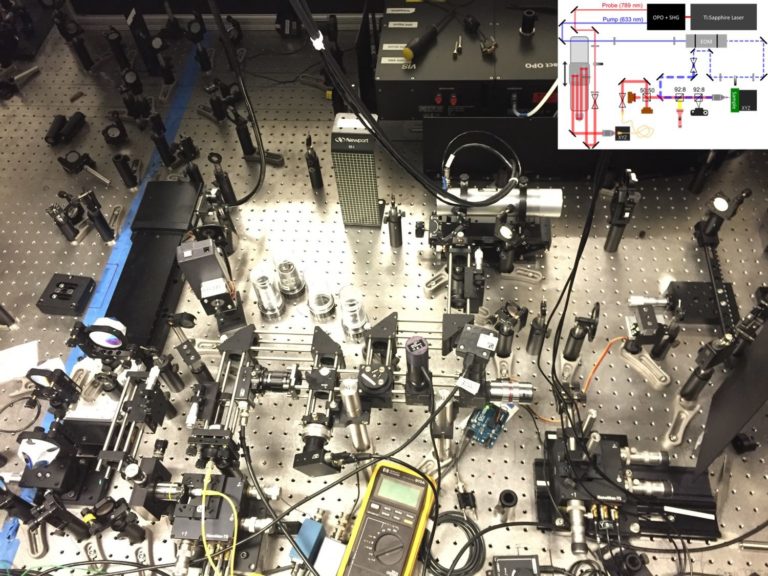

Time Domain Thermoreflectance

The Time Domain Thermoreflectance (TDTR) method [1, 2] is a highly sensitive ultrafast laser pump-probe technique for measuring the thermal conductivity and thermal boundary conductance of highly thermally conductive and/or small (down to single nm thick) samples and interfaces. We use the TDTR system located within the Imaging and Manipulation of Nanostructures facility at the Molecular Foundry at LBL. The system has a full optical delay up to 3.3 nanoseconds, continuously tunable pump and probe wavelengths from UV to near IR, modulation frequencies from 400 kHz to 10 MHz, and is compatible with an optical cryostat for extreme temperature and high vacuum measurements. We also have multiple sample objectives allowing laser spot 1/e2 radii ranging from 2 microns to 20 microns.

The Time Domain Thermoreflectance (TDTR) method [1, 2] is a highly sensitive ultrafast laser pump-probe technique for measuring the thermal conductivity and thermal boundary conductance of highly thermally conductive and/or small (down to single nm thick) samples and interfaces. We use the TDTR system located within the Imaging and Manipulation of Nanostructures facility at the Molecular Foundry at LBL. The system has a full optical delay up to 3.3 nanoseconds, continuously tunable pump and probe wavelengths from UV to near IR, modulation frequencies from 400 kHz to 10 MHz, and is compatible with an optical cryostat for extreme temperature and high vacuum measurements. We also have multiple sample objectives allowing laser spot 1/e2 radii ranging from 2 microns to 20 microns.

FTIR Spectrometer with Extended Range

FTIR spectrometer with extended spectral range for transmittance and reflectance measurements from 0.4 um to 20 um. Optical properties measured in a wide temperature range from 77 K to 1000K, in ambient and vacuum conditions. Capable of measuring specular, diffuse, and hemispherical optical properties.

FTIR spectrometer with extended spectral range for transmittance and reflectance measurements from 0.4 um to 20 um. Optical properties measured in a wide temperature range from 77 K to 1000K, in ambient and vacuum conditions. Capable of measuring specular, diffuse, and hemispherical optical properties.

Sol1A Class ABB Solar Simulator

Oriel’s Sol1A™ Class ABB systems take solar simulation to the next level. Certified to IEC 60904-9 2007 Edition, JIS C 8912, and ASTM E 927-05 standards, these large area SOL 1A sources use a xenon lamp and proprietary filter to meet, efficiently and reliably, Class ABB performance parameters without compromising the 1 sun output power. The result is a cost-effective system designed for laboratory or production environments. Class ABB simulators with 2×2 in. to 8×8 in. output beams.

Oriel’s Sol1A™ Class ABB systems take solar simulation to the next level. Certified to IEC 60904-9 2007 Edition, JIS C 8912, and ASTM E 927-05 standards, these large area SOL 1A sources use a xenon lamp and proprietary filter to meet, efficiently and reliably, Class ABB performance parameters without compromising the 1 sun output power. The result is a cost-effective system designed for laboratory or production environments. Class ABB simulators with 2×2 in. to 8×8 in. output beams.

Discovery Hybrid Rheometer HR-2

The Discovery Series Hybrid Rheometer (DHR) from TA instruments combines an advanced drag cup motor, a second generation magnetic bearing, force rebalance transducer (FRT), and the new patent-pending True Position Sensor (TPS) in a single-head Hybrid rheometer. The DHR provides very good direct strain control, direct stress control, and normal force measurement accuracy. Its an outstanding rheometer for a wide range of analytical, research, and production uses.

The Discovery Series Hybrid Rheometer (DHR) from TA instruments combines an advanced drag cup motor, a second generation magnetic bearing, force rebalance transducer (FRT), and the new patent-pending True Position Sensor (TPS) in a single-head Hybrid rheometer. The DHR provides very good direct strain control, direct stress control, and normal force measurement accuracy. Its an outstanding rheometer for a wide range of analytical, research, and production uses.

The Group Server

We have a dedicated server primarily used for machine learning computations and complex numerical simulations, equipped with:

- Four CPUs (Intel Xeon CPU E7-8890 v4 @ 2.20GHz), each with 24 cores (96 cores total)

- GPU with 24GB of memory, NVIDIA Titan RTX

- 528 GB RAM memory

- 10 TB solid-state storage

Differential Scanning Calorimetry (DSC)

The DSC 2500 measures heat flow with respect to the temperature of a sample. By tracking the heat flow, thermal events of a material can be detected and quantified. For example, a DSC can easily measure heat capacity, glass transitions, solid-solid transitions, solid-liquid transition, and phase separation, along with the enthalpy associated with each transition. Our lab uses the DSC to determine transition temperatures and enthalpies of novel phase change materials, along with the heat capacities of new heat transfer fluids.

The DSC 2500 measures heat flow with respect to the temperature of a sample. By tracking the heat flow, thermal events of a material can be detected and quantified. For example, a DSC can easily measure heat capacity, glass transitions, solid-solid transitions, solid-liquid transition, and phase separation, along with the enthalpy associated with each transition. Our lab uses the DSC to determine transition temperatures and enthalpies of novel phase change materials, along with the heat capacities of new heat transfer fluids.

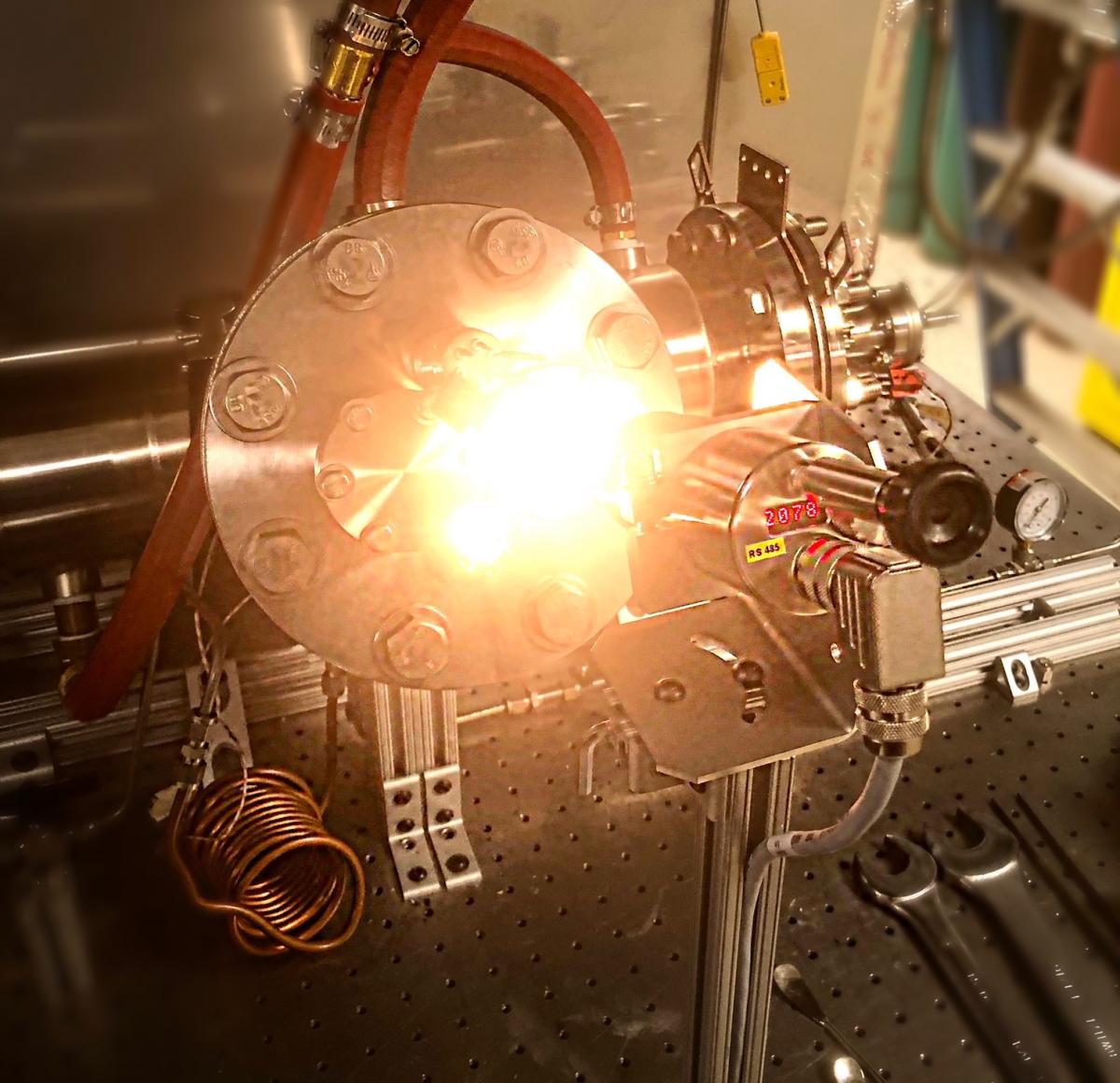

Tube Furnace

Our house-built tube furnace is capable of reaching stable temperatures over 2000°C. This furnace is regularly used for sintering pellets and driving endothermic gas reactions. The setup includes tools for gas, temperature, and electrical measurements and controls. Our infrared pyrometer is capable of measuring temperatures up to 3000°C.

Compact Tube Furnace

The MTI 1700C Max. Compact Tube Furnace is able to reach stable temperatures up to 1700°C. The temperature controller is a 30 segment programmable high precision SCR (Silicon Controlled Rectifier) digital controller with an accuracy of +/-1°C. The furnace can be operated under vacuum and other gas conditions. The custom-built Alumina Testing Fixture enables thermal/electrical property measurements for samples under various temperature and pressure conditions.

The MTI 1700C Max. Compact Tube Furnace is able to reach stable temperatures up to 1700°C. The temperature controller is a 30 segment programmable high precision SCR (Silicon Controlled Rectifier) digital controller with an accuracy of +/-1°C. The furnace can be operated under vacuum and other gas conditions. The custom-built Alumina Testing Fixture enables thermal/electrical property measurements for samples under various temperature and pressure conditions.

Thermogravimetric Analysis/Differential Scanning Calorimetry

Mettler Toledo TGA/DSC 3+ (Themogravimetric Analysis/Differential Scanning Calorimetry) coupled with modular humidity generator (ProUmid MHG32) is a thermal analysis tool capable of simultaneously measuring differential heat flow and mass change in small scale samples. The addition of the MHG allows for precise humidity control within the furnace within ± 0.8% RH at ambient temperatures. With the humidity tool, the furnace can run up to 90°C. But it is also capable to run normal TGA measurements up to 1300°C by exchanging the TGA extensions. This system is compatible for those looking to investigate mass transfer behavior under different atmospheric conditions and couple it with any exothermic/endothermic events.

Environmental Chambers

2 programmable benchtop environmental chambers (Thermotron SM-1.0-8200 and AES LH-1.5) have a workspace volume of 25L and 38.79L respectively. Each of the units possess a programmable controller which allows for long cycling conditions between -20°C to 94°C at 10 to 95%RH (± 2% RH). Each controller also offers export methodology to monitor the environmental conditions within the chamber. These units are fit to run larger scale samples to investigate any transformations that may occur under different environmental conditions or rigorous cycling.

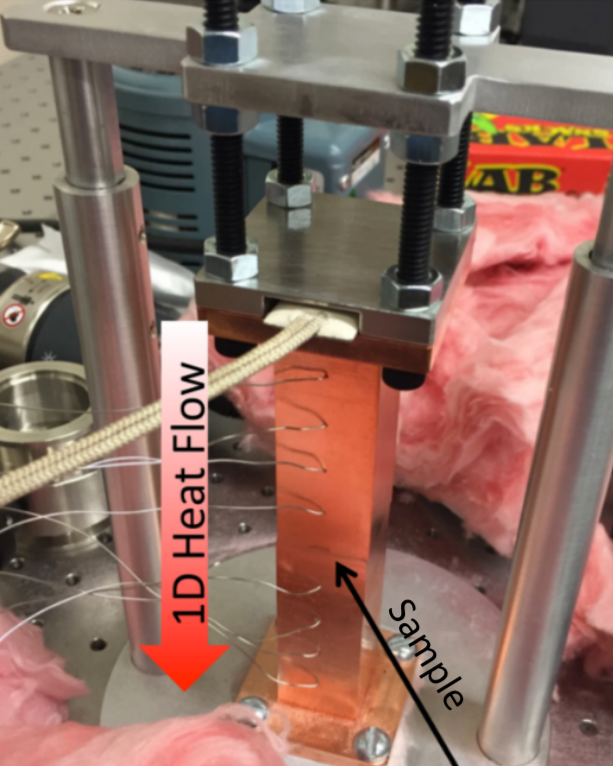

Cut Bar Measurement

The Cut Bar system uses an ex situ linear heat flow technique to measure the thermal conductivity of samples. The sample is placed between two 1 × 1 in. copper bars (Titanium bars are also available). 1D heat flows from the heater on the top, down through the bars and sample, and is dissipated through the metal base into the optical table. A series of eight thermocouples throughout the copper bars measure the bars’ internal temperatures. Approximately, 1 in. of fiberglass insulation wraps all around the apparatus during measurement for thermal isolation from the environment. The recorded temperature gradients are typically stable to less than 0.5% fluctuation. The temperature gradient in the bottom bar is recorded to calculate the heat flux, Q, using the known copper thermal conductivity. A typical heat flux used is 12 W, resulting in a temperature drop of approximately ΔT = 20 K across the sample.

The Cut Bar system uses an ex situ linear heat flow technique to measure the thermal conductivity of samples. The sample is placed between two 1 × 1 in. copper bars (Titanium bars are also available). 1D heat flows from the heater on the top, down through the bars and sample, and is dissipated through the metal base into the optical table. A series of eight thermocouples throughout the copper bars measure the bars’ internal temperatures. Approximately, 1 in. of fiberglass insulation wraps all around the apparatus during measurement for thermal isolation from the environment. The recorded temperature gradients are typically stable to less than 0.5% fluctuation. The temperature gradient in the bottom bar is recorded to calculate the heat flux, Q, using the known copper thermal conductivity. A typical heat flux used is 12 W, resulting in a temperature drop of approximately ΔT = 20 K across the sample.